In drone operations, the flight tower serves as the "control center," and its stability directly affects flight safety and operational efficiency. However, many users often encounter problems such as communication interruptions, data anomalies, and startup failures during daily use, which not only delay the operation progress but also may cause the risk of equipment damage. This article sorts out the high-frequency usage pain points of flight towers and provides targeted solutions based on practical experience to help you quickly troubleshoot problems and reduce troubles.

Sudden "Disconnection" During Flight, Interrupted Communication Between Flight Tower and Remote Controller

Problem Manifestation

After the drone takes off, the flight tower suddenly loses signal connection with the remote controller. The remote controller screen displays "Communication Interrupted," and the drone may enter the "out-of-control return" mode. In complex environments, it may also face the risk of collision. This type of problem mostly occurs in long-distance operations (such as plant protection and surveying) or scenarios with strong electromagnetic interference (such as near high-voltage towers and industrial areas).

Quick Solutions

Prioritize Checking for Signal Interference Sources: Stop the operation immediately and observe the surrounding environment. If there are high-voltage towers, base stations, or large industrial equipment nearby, try moving 50-100 meters away from the interference source. Restart the communication module of the flight tower and the remote controller (usually by long-pressing the "Communication Reset" button on the remote controller for 3 seconds). In most cases, the connection can be restored.

Check Hardware Connections and Antenna Status: After landing, remove the flight tower shell and check if the cable of the communication module is loose (especially after long-term use, vibration may cause poor interface contact). Reinsert the cable and fasten the buckle tightly. At the same time, check if the remote controller antenna is fully extended and not bent. If the antenna is damaged (such as a broken shell or deformed signal pin), replace it with a spare antenna in a timely manner.

Downgrade Communication Frequency Band for Emergency: If a dual-band (2.4G + 5.8G) flight tower is used, when the 5.8G frequency band is disconnected due to interference, you can manually switch to the 2.4G frequency band in the remote controller settings. The 2.4G frequency band has stronger penetration, making it suitable for complex environments, although its transmission distance is slightly shorter, it can temporarily ensure basic communication.

Preventive Suggestions

Before daily operations, use the flight tower's supporting APP to detect the communication signal strength (it is recommended to take off only when the signal value is ≥ -80dBm). For long-term operations in interference scenarios, you can install an "electromagnetic shield" on the flight tower (industrial-grade flight tower adapters are available on e-commerce platforms) to reduce the impact of external interference.

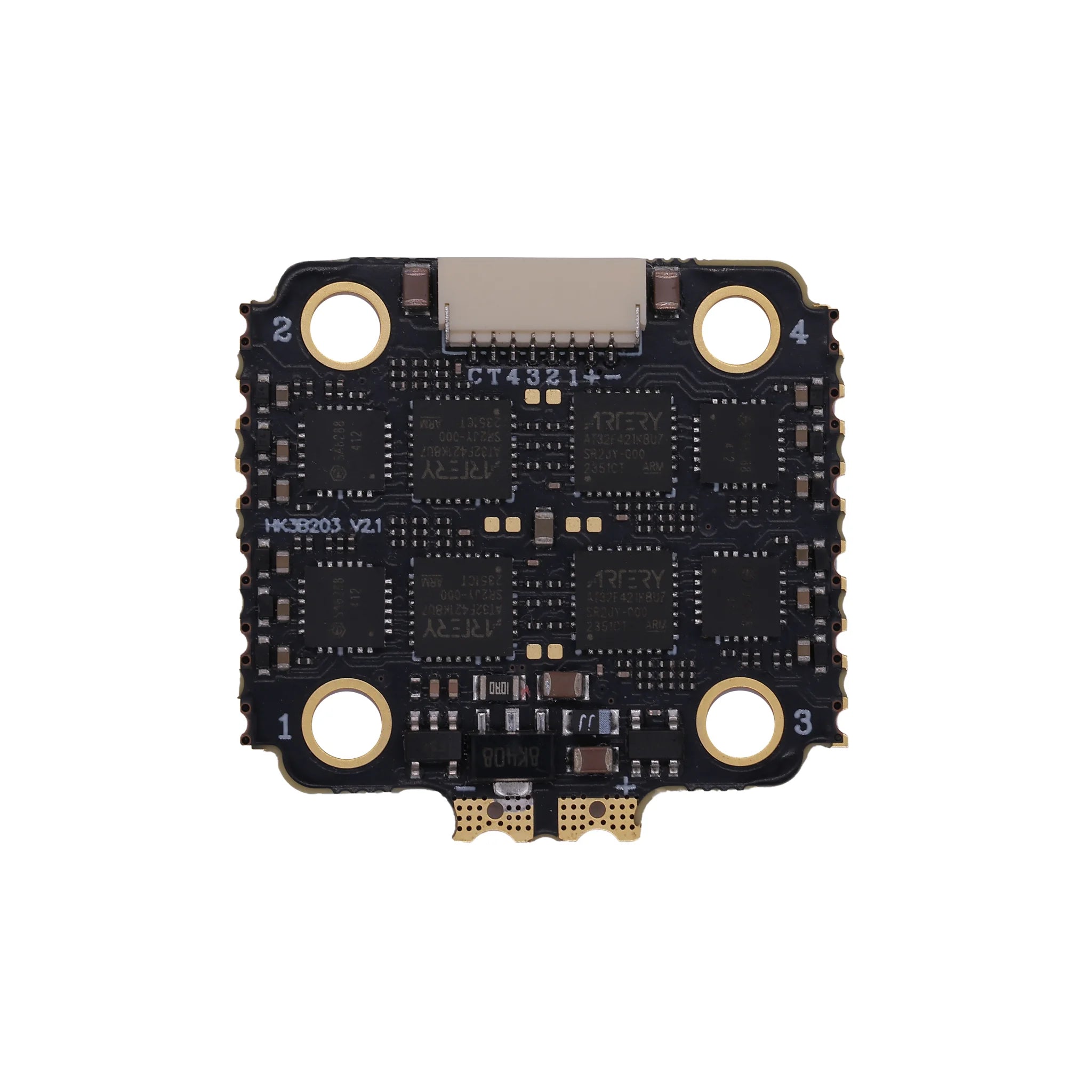

Hakrc 60A Mini F7 V2 Fly Tower

Flight Tower Data Anomalies, Task Data Loss or Inaccurate Collection

Problem Manifestation

After the operation is completed, the aerial images, GPS tracks, and sensor data (such as plant protection flow rate and inspection temperature) stored in the flight tower are partially lost, or the data does not match the actual scenario (such as GPS positioning deviation exceeding 10 meters, and temperature data showing "abnormal values"), making subsequent data analysis unable to be carried out normally.

Quick Solutions

Data Recovery: Check "Temporary Cache" First, Then Use Tools for Repair: If data is lost, first check the "temporary cache directory" of the flight tower (most flight towers can find it in "Settings - Storage Management"). Some flight towers will automatically save temporary data that has not been completely written. After finding it, manually export it to the computer. If there is no data in the cache, you can use data recovery software (such as DiskGenius, or the "data repair tool" supporting the flight tower manufacturer) to scan the flight tower memory card. There is a probability of more than 70% to recover mistakenly deleted or slightly damaged data.

Inaccurate Positioning: Calibrate GPS and IMU Sensors: If the GPS deviation is too large, first confirm whether the flight tower is in an "open and unobstructed environment" (away from high-rise buildings and trees). Then initiate "GPS Recalibration" in the APP (usually requiring the drone to stand still horizontally for 30 seconds, and then complete the "figure-eight flight" calibration according to the prompts). If the deviation still exists after calibration, check whether the IMU (Inertial Measurement Unit) is offset. Enter the "Sensor Calibration" interface and complete the "Horizontal Calibration" and "Six-Side Calibration" step by step to eliminate the impact of sensor drift.

Abnormal Sensor Data: Check Interfaces and Parameter Settings: If the temperature, flow rate, and other sensor data are abnormal, first check whether the interface between the sensor and the flight tower is plugged in tightly (some sensors need to distinguish between positive and negative poles; reverse insertion will cause data errors). Then check the "sensor parameter configuration" in the flight tower APP (for example, the plant protection flow sensor needs to set the "unit conversion coefficient"; if the coefficient is wrong, the data will be doubled or halved). Re-adjust the parameters according to the sensor manual and restart the flight tower.

Preventive Suggestions

Before each operation, enable the "Automatic Backup" function in the flight tower APP (synchronize data to the cloud or local memory card in real time). When using an industrial-grade flight tower, choose a model with the "data verification" function (which can automatically detect data integrity and pop up a reminder when abnormalities are found).

Hakrc 50A F7 V2 Fly Tower

Flight Tower Startup Failure, No Response or Error Report After Power-On

Problem Manifestation

After powering on the drone, the flight tower indicator light does not turn on and there is no startup sound, or the indicator light flashes an "error code" (such as 3 red flashes indicating "power supply abnormality"), and it cannot enter the normal working state, directly preventing the operation from starting.

Quick Solutions

Power Supply Issue: Troubleshoot from Battery to Interface One by One: First, check whether the drone battery has sufficient power (if the power is less than 20%, some flight towers will activate the "low-power protection" and refuse to start). Replace with a fully charged battery and try again. If there is still no response, check whether the flight tower power interface is damaged (such as bent pins or oxidation). Wipe the interface with a cotton swab dipped in alcohol to remove the oxide layer. You can also use a multimeter to measure the voltage of the power supply line (the common power supply voltage of flight towers is 12V or 24V). If the voltage is 0, the power line may be disconnected, and the spare power line needs to be replaced.

Firmware Issue: Forcibly Flash to Restore Factory Version: If the flight tower displays a "Firmware Error" after power-on (such as the screen showing "Firmware Error"), it is mostly caused by a failed firmware update. At this time, connect the flight tower to the computer via a USB cable, open the "firmware repair tool" provided by the manufacturer, and select "Forcibly Flash Factory Firmware" (do not power off during the process, otherwise the flight tower will be bricked). After the flashing is completed, restart the flight tower, and it can usually return to normal.

Hardware Failure: Emergency Replacement of Key Components: If none of the above methods work, the flight tower main control chip or power module may be damaged. For DIY flight tower users, you can replace the spare main control board (which must be consistent with the original model). For industrial-grade flight tower users, you can contact the manufacturer's after-sales service, provide the "error code" and usage scenario, and most manufacturers will provide an "emergency replacement part" service to reduce downtime.

Preventive Suggestions

Ensure that the battery power is ≥ 50% during firmware update, and avoid disconnecting the connection during the update process. When storing the flight tower daily, avoid dropping and squeezing it. If it is not used for a long time, power it on once a month (to prevent hardware damage caused by capacitor power loss).

Harkc 65A F4 V2 Fly Tower

Flight Tower Overheating, Frequent Triggering of "High-Temperature Protection" During Operation

Problem Manifestation

In high-temperature environments in summer (such as plant protection operations at noon) or after long-term operations (more than 1 hour), the flight tower indicator light shows "high-temperature alarm" (such as a steady yellow light), and then automatically reduces performance (such as reducing data transmission rate) or even shuts down forcibly, affecting the continuity of operations.

Quick Solutions

Temporary Cooling: Physical Heat Dissipation + Reduce Load: Stop the operation immediately, move the drone to a cool place, open the flight tower shell (if it is a sealed flight tower, you can remove the top heat dissipation cover), and blow the flight tower with a fan for 10-15 minutes. Restart it after the temperature drops below 40℃ (some flight tower APPs can display the real-time temperature). If you need to continue the operation, you can temporarily turn off "non-essential functions" (such as real-time image transmission and redundant sensor detection) to reduce the computing load of the flight tower and lower heat generation.

Long-Term Optimization: Install Heat Dissipation Accessories: DIY users can install "heat sinks + small heat dissipation fans" on the flight tower (choose 5V low-power models to avoid increasing the power supply burden) and paste them on the surface of the main control chip and communication module. Industrial-grade flight tower users can replace with upgraded models with the "active heat dissipation" function (such as built-in heat dissipation fans and heat pipe heat dissipation structures), which are suitable for high-temperature areas or long-term operation scenarios.

Preventive Suggestions

During summer operations, try to avoid the high-temperature period from 12:00 to 14:00 at noon. When supplying power to the flight tower, choose a power module with the "voltage stabilization" function (excessive voltage fluctuations will increase the heat generation of the flight tower).

Summary: The "3-Step Principle" for Solving Flight Tower Problems

When encountering flight tower usage problems, there is no need to panic. You can follow the steps of "first check external factors (environment, connection) → then handle software settings (parameters, firmware) → finally check hardware failures (components, modules)" to quickly locate and solve most problems. At the same time, doing a good job in the daily cleaning, calibration, and maintenance of the flight tower can greatly reduce the incidence of failures and make drone operations more efficient and secure.