The Electronic Speed Controller (ESC) of a drone, as a core component connecting the flight controller and the motor, plays a crucial role in regulating motor speed and ensuring circuit safety. However, during long-term use, issues such as dust accumulation, high-temperature overload, and improper storage often lead to ESC performance degradation or even burnout, directly affecting the drone's flight safety and operational costs. This article will provide a scientific and practical ESC lifespan extension solution from three core dimensions—daily cleaning, heat dissipation optimization, and storage maintenance—to help pilots avoid common wear risks and maximize the service life of the equipment.

Daily Cleaning: Reducing ESC Wear from the "Source"

ESC wear often starts with "minor contamination"—dust, oil, and moisture attached after flights can gradually block heat dissipation holes, corrode circuit boards, and eventually cause short circuits or component aging. The core goal of daily cleaning is to "timely remove contaminants and avoid secondary damage," and targeted operations should be adopted based on different usage scenarios.

Basic Cleaning: "5-Minute Maintenance" Must-Be-Done After Each Flight

After each flight (especially in complex environments such as sandy areas, farmlands, and coastal regions), basic cleaning of the ESC must be performed immediately, following these steps:

Power-Off Inspection: First, disconnect the drone's battery and remove the propellers to ensure the ESC is completely powered off, preventing accidental contact with the circuit during cleaning.

Surface Dust Removal: Use a dry soft brush (e.g., a camera lens brush) to gently sweep away dust from the ESC surface, heat dissipation holes, and terminal connections. Focus on cleaning particles in the gaps of the heat sink (dust accumulation can reduce heat dissipation efficiency by more than 30%).

Mild Stain Removal: If there is oil or mud on the surface, gently wipe it with a lint-free cloth dipped in anhydrous alcohol (alcohol is highly volatile, which prevents moisture residue). Never rinse or soak directly with water.

Terminal Protection: When cleaning terminal connections (e.g., XT60, XT90 interfaces), use a cotton swab dipped in alcohol to wipe the metal contacts and remove the oxide layer, preventing local overheating caused by poor contact.

Deep Cleaning: "Comprehensive Maintenance" Every 30 Flight Cycles

After the drone has accumulated 30 flight cycles (or a single flight exceeds 2 hours), deep cleaning is required, focusing on "hidden contamination areas":

Disassembly and Inspection: If the ESC is detachable (e.g., independent ESCs for multi-rotor drones), it can be gently removed to check for dust accumulation at the contact area between the bottom and the frame (this area is prone to high temperatures due to poor ventilation).

Gap Cleaning: Use a compressed air can (with a pressure not exceeding 0.5MPa) to blow air into the ESC's heat dissipation holes and component gaps to remove deep-seated dust (note to keep a distance of more than 10cm to avoid damaging components).

Moisture-Proof Treatment: After flying in humid environments (e.g., rainy days, coastal areas), place the ESC in a dry and ventilated area for 2 hours after cleaning, or use a hair dryer (on the cold air setting) to dry the moisture in the gaps, preventing moisture corrosion of the circuit board.

Precautions: Never use hard brushes, screwdrivers, or other tools to scrape the circuit board during cleaning, as this may damage component solder joints. If the ESC surface has a waterproof coating, wait for the coating to dry completely before reinstalling the ESC after alcohol wiping.

Heat Dissipation Optimization: Addressing the "Biggest Killer" of ESCs—High Temperature

The core wear of ESCs stems from "high-temperature overload": when the motor load is too high and heat dissipation is poor, the temperature of the MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) inside the ESC rises sharply. Permanent damage is likely to occur when the temperature exceeds 120°C, and direct burnout may happen when it exceeds 150°C. The key to heat dissipation optimization is to "reduce operating temperature and improve heat dissipation efficiency," which needs to be achieved from two aspects: "hardware modification" and "flying habits."

Hardware Optimization: Building an "Efficient Heat Dissipation System" for the ESC

According to the drone's usage scenarios (e.g., racing drones, aerial photography drones, agricultural spray drones), select a suitable heat dissipation solution. Common optimization methods are as follows:

Adding Heat Sinks: For small ESCs without built-in heat sinks (e.g., ESCs below 20A for racing drones), attach a thermal silica pad (0.5-1mm thick) and then install an aluminum heat sink (with an area not less than 1.5 times the ESC surface area), which can improve heat dissipation efficiency by 40%.

Optimizing Heat Dissipation Airflow: In the frame design, ensure there is sufficient ventilation space around the ESC (it is recommended that the distance from other components is not less than 5mm) to avoid being surrounded by heat sources such as batteries and motors. For enclosed frames (e.g., foldable aerial photography drones), open ventilation holes at the corresponding positions of the ESC, or install a micro cooling fan (5V, below 0.1A, to avoid adding additional load).

Using High Thermal Conductivity Materials: Replace the plastic gasket at the contact area between the ESC and the frame with a copper or aluminum thermal pad to use the frame for auxiliary heat dissipation (especially suitable for high-power equipment such as agricultural spray drones). For multi-rotor drones, fix the ESC on the metal beam of the frame to quickly dissipate heat through metal conduction.

Flying Habits: 4 Keys to Avoiding "High-Temperature Working Conditions"

After hardware optimization, scientific flying habits can further reduce the ESC load and minimize high-temperature risks. The core principle is to "avoid long-term full-load operation":

Controlling Flight Duration: Select a reasonable flight time based on the ESC's rated current. For example, an aerial photography drone with a 2216 motor and a 40A ESC should have a single flight time not exceeding 25 minutes (reserve 20% battery capacity to avoid ESC overload caused by low battery voltage).

Avoiding Extreme Loads: Avoid frequent "aggressive operations" such as long-term vertical climbing and high-speed diving (such operations will cause the motor load to increase sharply, and the ESC current will exceed 1.5 times the rated value in an instant). When flying a racing drone, the duration of a single continuous stunt (e.g., rolling, sharp turning) should not exceed 5 seconds, and there should be an interval of more than 10 seconds before the next set of stunts.

Real-Time Temperature Monitoring: Install a temperature sensor (e.g., DS18B20) on the ESC and check the temperature in real time through the flight controller APP. Immediately reduce the flight intensity when the temperature exceeds 80°C, and force a landing when it exceeds 100°C.

Timely Shutdown for Cooling: If the ESC feels abnormally hot during flight (a stinging sensation is felt when touching it for more than 1 second) or abnormal motor noise is heard, shut down immediately and check for faults after the ESC cools down to room temperature (avoid continuing to use it at high temperatures to prevent aggravated damage).

Data Reference: Actual tests show that after adding a heat sink and optimizing the airflow, the temperature of the ESC during full-load operation can be reduced by 30-40°C, and its service life can be extended by 2-3 times. Avoiding aggressive operations can increase the ESC's Mean Time Between Failures (MTBF) by more than 50%.

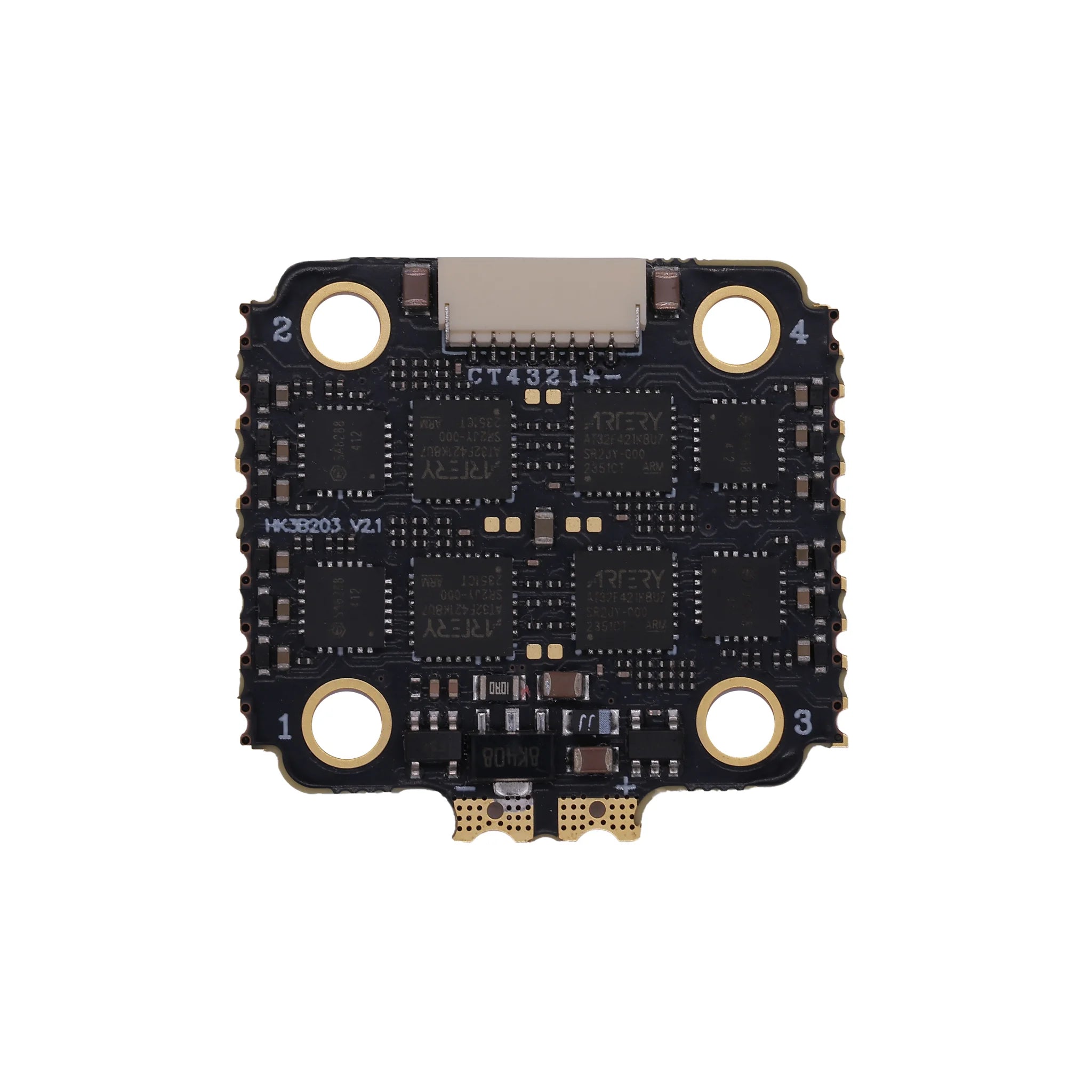

Hakrc 5139 90A 4in1 FPV ESC

Storage Maintenance: "Lifespan Protection" During Long-Term Idleness

When a drone is idle for a long time (more than 1 month), the ESC is prone to problems such as battery over-discharge, component oxidation, and capacitor aging if it is in an "improper storage state." The core of storage maintenance is to "create a stable environment and eliminate potential wear," and the full-process specifications of "pre-storage preparation - in-storage management - pre-activation inspection" should be followed.

Pre-Storage Preparation: 3-Step "Damage Prevention"

Discharging to Safe Voltage: If the ESC is connected to a battery (e.g., an integrated flight controller ESC), discharge the battery to 3.8-3.85V per cell (the safe storage voltage for lithium batteries) to prevent battery leakage caused by long-term full charge or over-discharge, which may corrode the ESC circuit board.

Cleaning and Applying Protective Agent: After deep cleaning, apply a thin layer of anti-rust agent (e.g., WD-40 Precision Electrical Anti-Rust Agent) to the metal terminals and solder joints of the ESC to prevent oxidation. For outdoor storage, wrap the ESC surface with a moisture-proof film (e.g., plastic wrap), but be sure to reserve ventilation holes to avoid moisture accumulation.

Securing Component Positions: Check if components such as capacitors and resistors inside the ESC are loose. If there is a cold solder joint, re-solder it with a soldering iron. Organize and fix the ESC's motor wires and signal wires to avoid internal wire breakage caused by long-term bending.

In-Storage Environment Management: Avoiding "3 Major Taboos"

Temperature Taboo: The storage environment temperature should be controlled between 5-30°C, avoiding long-term exposure to high temperatures (exceeding 40°C) or low temperatures (below 0°C). High temperatures will accelerate capacitor aging, while low temperatures will cause electrolyte solidification, affecting component performance.

Humidity Taboo: The relative humidity should not exceed 60%, and storage in humid areas such as basements and bathrooms should be avoided. Desiccants (e.g., silica gel desiccants) can be placed in the storage box and replaced every 1-2 months.

Magnetic Field Taboo: Keep away from strong magnetic field environments (e.g., transformers, microwave ovens, magnets) to prevent the Hall sensor inside the ESC (used for motor speed measurement) from being magnetized, which may lead to a decrease in speed control accuracy.

Pre-Activation Inspection: "Safe Activation" After Idleness

When the drone has been idle for more than 1 month, a comprehensive inspection of the ESC is required before activation. Only after confirming that there are no faults can it be reinstalled for flight:

Visual Inspection: Check if there are signs of bulging, leakage, or rust on the ESC surface, and if the terminal connections are oxidized and blackened.

Continuity Test: Use a multimeter (in resistance mode) to test whether the ESC's power input terminal and motor output terminal are short-circuited (the resistance should be greater than 100Ω under normal circumstances). If a short circuit is detected, stop using it immediately and troubleshoot.

No-Load Test: Connect the ESC to the flight controller and motor (without installing the propeller), power it on, and slowly adjust the throttle through the remote control. Observe whether the motor speed is stable and if there is any abnormal noise. If the speed fluctuates significantly or there is jamming, re-calibrate the ESC (refer to the ESC calibration tutorial of the corresponding brand).

Conclusion: The "Core Logic" of Extending ESC Lifespan

The essence of extending the lifespan of a drone's ESC is to "reduce wear factors and strengthen protective measures"—daily cleaning addresses "contamination wear," heat dissipation optimization solves "high-temperature wear," and storage maintenance tackles "idle wear." Combining these three aspects can extend the average service life of the ESC from 1-2 years to 3-5 years, which not only reduces equipment replacement costs but also avoids the risk of crashes caused by ESC faults during flight.

For pilots, it is necessary to develop the habit of "cleaning after flights, monitoring temperature during flights, and maintaining during idleness." At the same time, the maintenance frequency should be adjusted according to the drone's usage intensity (e.g., commercial agricultural spray drones that fly 8 hours a day require deep cleaning once a week). Remember: the lifespan of the ESC lies in every careful maintenance session.