In a drone system, the motor is the "muscle" that provides power, while the Electronic Speed Controller (ESC) acts as the "neural center" controlling the muscle. It is responsible for real-time adjusting the motor speed to ensure the drone flies stably or moves at high speed. The following briefly explains its core logic and key information.

Core Position of ESC: The "Translator" Between Flight Controller and Motor

Drone flight control follows the logic of "Command → Calculation → Execution": The flight controller calculates the required motor speed based on remote control commands and sensor data; the ESC converts the low-voltage PWM signal (50Hz frequency, 1-2ms pulse width) output by the flight controller into a high-voltage drive signal that the motor can recognize.

The ESC is essentially a "power converter": After receiving the PWM signal, it converts the high-voltage DC power from the battery (e.g., 11.1V, 22.2V) into adjustable AC power to drive the brushless motor. Since mainstream drones use brushless motors, which require AC power to operate, the ESC is the key component for realizing "DC-to-AC conversion" and current adjustment.

Core Working Process of ESC: Four Steps to Achieve Speed Control

Signal Reception: It receives the PWM signal from the flight controller via a 3Pin/4Pin interface. A 1ms pulse width corresponds to the minimum speed (idle speed), a 2ms pulse width corresponds to the maximum speed, and the speed changes linearly with the pulse width between 1-2ms (some support non-linear adjustment).

Speed Calculation: The Microcontroller Unit (MCU) converts the pulse width signal into a target speed (e.g., 1.5ms corresponds to 5000 revolutions per minute). Then, it obtains the actual speed through a Hall sensor or a sensorless algorithm, compares the two speeds, and determines whether to adjust the power.

Power Conversion: Six MOSFET transistors (3 in the upper bridge arm and 3 in the lower bridge arm) are turned on and off alternately at high frequency, "chopping" the DC power into three-phase AC power with a 120° phase difference to drive the motor rotor. The switching frequency needs to balance "operation stability" and "MOSFET heat dissipation".

Speed Adjustment: A closed-loop control is adopted. When the actual speed is lower than the target speed, the on-time of the MOSFET transistors is increased (to raise current and power); when it is higher than the target speed, the on-time is reduced. High-end ESCs also support reverse conduction braking to facilitate emergency hovering or landing.

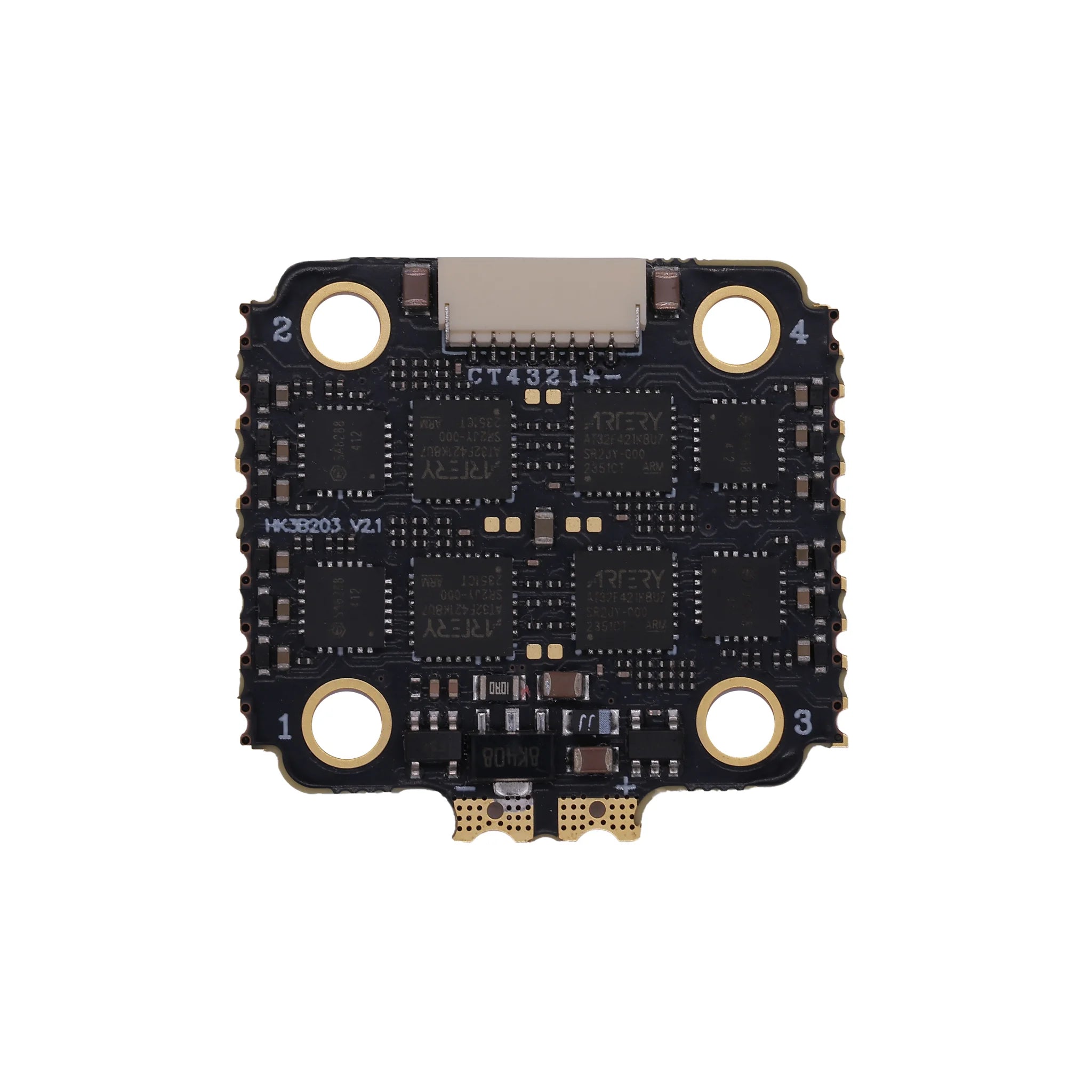

Hakrc 5139 110A 4in1 FPV ESC

Key Technologies Affecting ESC Performance

Drive Methods:

Sensored drive (relying on Hall sensors, stable startup, good low-speed performance, suitable for aerial photography).

Sensorless drive (relying on back electromotive force, low cost, high reliability, suitable for racing, may jitter during startup). Most mainstream consumer-grade ESCs use the "sensorless + startup assistance" mode.

Current Protection: When the load is too high (e.g., propeller stuck, collision) causing the current to exceed the threshold (30A/60A, etc.), it cuts off the output or reduces power to protect the MOSFETs and the battery.

Communication Protocols: From the early analog PWM signals, it has been upgraded to digital protocols such as DSHOT (strong anti-interference, low delay, supports data telemetry), Multishot (suitable for racing), and CAN bus (centralized control for large multi-motor drones).

Hakrc 3220 65A 4in1 FPV ESC

Common Faults and Troubleshooting

Motor Not Rotating: Check the signal wire (looseness/breakage), power supply (battery voltage, interface contact), and motor (jamming may indicate damaged bearings or short-circuited coils).

Motor Jitter: Re-calibrate the throttle range; repair or replace the Hall sensor or switch to sensorless mode; check the propeller (installation, damage).

ESC Overheating: Add ventilation holes to the fuselage, install heat sinks/fans; replace with a suitable propeller to avoid motor overload.

Conclusion

The ESC is the core of the drone's power system. Through signal conversion, power adjustment, etc., it converts the flight controller's commands into motor power. Currently, it is evolving towards "high power density, fast response, and intelligent monitoring" to provide support for drones in various scenarios. Understanding its principle can help users troubleshoot faults, optimize parameters, and understand the drone's flight logic.