In the selection of drone power systems, single ESCs (Electronic Speed Controllers) and 4-in-1 ESCs are not a matter of "which is better," but "which is more suitable for your needs." The core difference between the two revolves around "flexibility" and "integration efficiency." Their advantages and disadvantages in different scenarios directly affect flight experience, assembly costs, and long-term maintenance. This article will analyze six key user needs and combine the pros and cons of both ESC types to help you find the optimal choice.

Clarify the Core: Basic Comparison of Advantages and Disadvantages Between Single ESC and 4-in-1 ESC

Before analyzing specific needs, it is essential to understand the fundamental differences between the two ESC types—this serves as the key basis for subsequent selection:

|

Dimension |

Single ESC (Individual ESC) |

4-in-1 ESC (Integrated 4-Channel ESC) |

|

Core Advantages |

1. Flexible matching: Can mix ESCs of different brands and current ratings2. Low maintenance cost: Only replace the faulty unit if one fails3. Distributed heat dissipation: Less prone to concentrated overheating4. Supports multi-rotor expansion (hexacopters, octocopters) |

1. Efficient assembly: Fewer wires and simpler steps, easy for beginners2. Lightweight: No redundant casings or wires, reducing weight by 10%-30%3. Space-saving: Compact size, suitable for small drones4. Stable signals: Optimized through integrated testing, low latency |

|

Core Disadvantages |

1. Complex assembly: 4 ESCs require separate wiring, easy to make connection errors2. Heavier weight: Independent casings and redundant wires increase load3. More space-consuming: Not suitable for small drone bodies4. Additional compatibility checks needed: Mixed use may cause issues |

1. High maintenance cost: Entire module must be replaced if any channel fails (cost ≈ 4 single ESCs)2. Concentrated heat dissipation: High temperatures easily affect overall performance3. No expandability: Only supports quadcopters, cannot adjust single channels4. Fixed parameters: Cannot optimize individual ESCs separately |

Select Based on Needs: Optimal Choices for 6 Scenarios

Scenario 1: Beginners/First-Time Assembly – Prioritize 4-in-1 ESC

Core Need: Reduce assembly difficulty and avoid component damage due to operational errors

The most common issue for beginners during assembly is "wiring confusion": Single ESCs require distinguishing between power, signal, and motor wires for 4 separate units, and aligning them with the flight controller’s CH1-CH4 channels. Wrong connections may burn the ESC or cause motor rotation errors. In contrast, 4-in-1 ESCs only need 3 types of wiring (1 main power cable, 1 flight controller signal cable, and 4 motor cables), with clear logic. Some brands even label "Arm 1-4" for easy identification, allowing beginners to complete wiring in 10 minutes.

Compromise on Disadvantages: Although maintenance costs are higher, well-assembled beginner drones are unlikely to fail quickly with normal use. Additionally, small entry-level drones (e.g., FPV drones with a wheelbase of 150-200mm) have limited space, and the lightweight advantage of 4-in-1 ESCs improves battery life—better aligning with beginners’ flight needs.

Scenario 2: DIY Enthusiasts/Customized Assembly – Prioritize Single ESCs

Core Need: Flexibly match power systems and pursue customized flight performance

DIY enthusiasts often adjust power configurations based on flight scenarios: For example, if they want a drone to "prioritize power for the front two motors (for racing) and battery life for the rear two (for hovering)," single ESCs allow pairing the front two motors with 30A high-current models and the rear two with 20A standard models—no need for full replacement. However, 4-in-1 ESCs have fixed specifications for all 4 channels, making "differentiated matching" impossible.

Furthermore, if a user wants to upgrade from a quadcopter to a hexacopter, single ESCs only require adding 2 more units. In contrast, 4-in-1 ESCs are completely incompatible and require purchasing a new 6-in-1 module (higher cost).

Compromise on Disadvantages: While assembly is complex, DIY enthusiasts typically have wiring and debugging skills. Moreover, distributed heat dissipation supports long-term operation of high-power motors (e.g., 2207 motors), preventing performance degradation due to overheating.

Scenario 3: Small/Micro Drones (FPV Racers, Mini Aerial Photography Drones) – Prioritize 4-in-1 ESC

Core Need: Lightweight design, space-saving, and improved maneuverability/battery life

Small drones (e.g., FPV racers with a wheelbase ≤200mm, DJI Mini clones) are extremely sensitive to "weight" and "space": 4 single ESCs (including casings and wires) weigh approximately 25-30g, while a 4-in-1 ESC of the same specification weighs only 12-15g. This weight reduction directly increases battery life by 5%-10%. Additionally, the compact design of 4-in-1 ESCs avoids cluttered wires in small drone bodies—some can even be installed directly under the flight controller, freeing up space for adding transmitters or batteries.

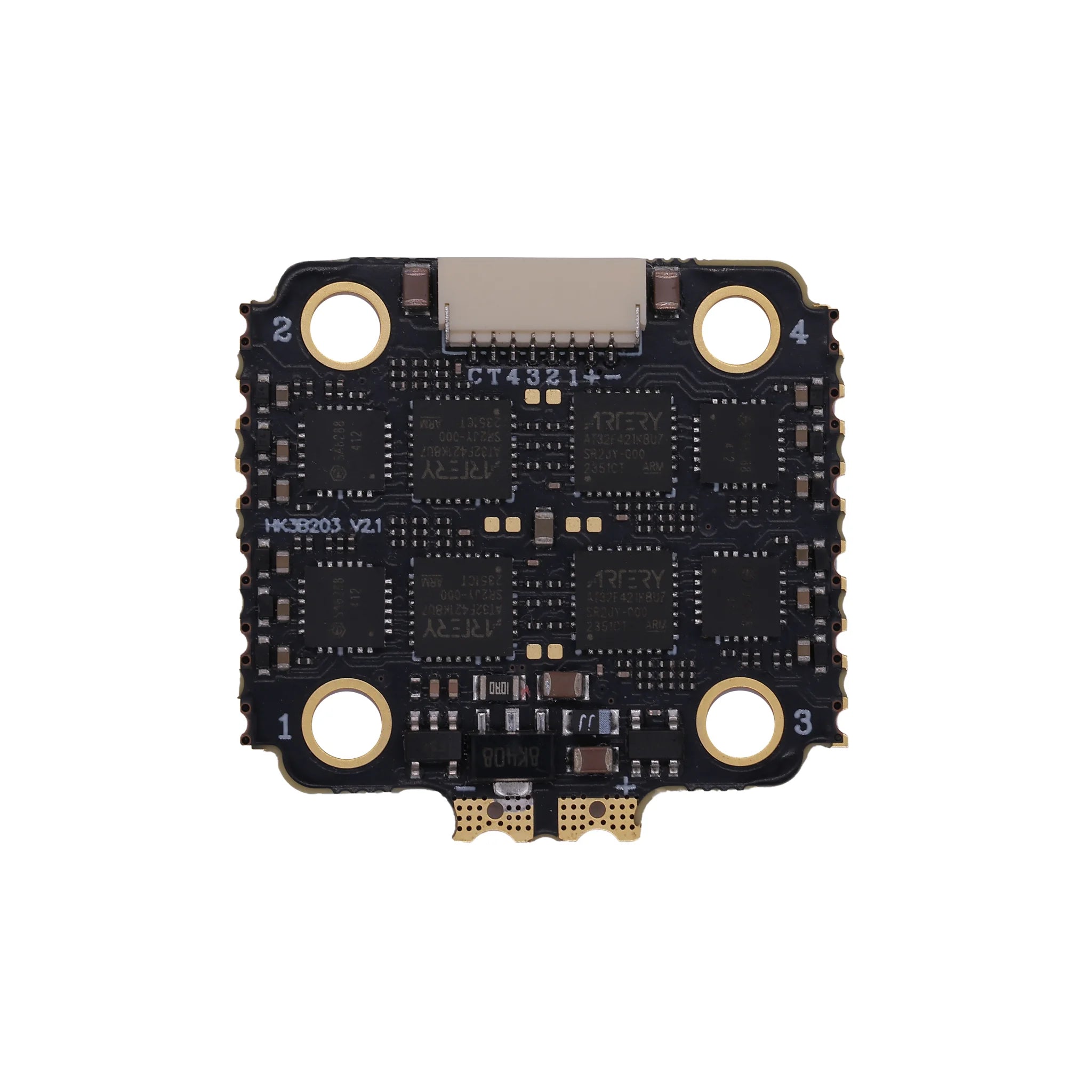

Compromise on Disadvantages: Heat dissipation issues can be solved by "choosing 4-in-1 models with heat sinks" (e.g., Holybro Tekko32 4-in-1 ESC with aluminum heat shells). Small drones also use low-power motors (usually ≤20A), generating less heat, so overheating is not a major concern.

Scenario 4: Medium/Large Drones (Payload ≥1kg, e.g., Agricultural Sprayers, Payload-Carrying Aerial Photography Drones) – Prioritize Single ESCs

Core Need: Strong heat dissipation, low maintenance costs, and support for high-power motors

Medium/large drones use high-power motors (e.g., 2806 motors), with a single ESC’s continuous current reaching over 40A during operation. If a 4-in-1 ESC is used, heat from 4 channels concentrates on one PCB board—even with heat sinks, high temperatures may trigger protection mechanisms, causing sudden motor speed reduction (endangering payload flight safety). In contrast, single ESCs can be installed separately on 4 arms, with each unit dissipating heat naturally through the arm’s metal material and airflow—resulting in a temperature 15-20℃ lower than 4-in-1 ESCs.

Additionally, if an ESC fails on a medium/large drone, replacing one single ESC costs only 50-80 yuan, while replacing a 4-in-1 ESC costs 200-300 yuan. Single ESCs thus offer lower long-term maintenance costs.

Scenario 5: Pursuit of Extreme Flight Stability (Professional Racing, Precision Aerial Photography) – Prioritize 4-in-1 ESC

Core Need: Low signal latency and no wire interference

Professional racing drones require "millisecond-level throttle response." The integrated design of 4-in-1 ESCs shortens signal transmission distance (only 5-10cm from flight controller to ESC). Branded products (e.g., Betaflight 4-in-1 ESC) optimize circuit layout and support high-speed DShot1200 protocol, with signal latency 8%-12% lower than single ESCs—enabling more precise attitude control for pilots. In contrast, single ESCs have scattered signal wires; length differences may cause unsynchronized response among 4 motors, affecting racing control accuracy.

In precision aerial photography scenarios, the "no cluttered wires" advantage of 4-in-1 ESCs prevents interference with GPS or transmitter signals, reducing aerial photo jitter or signal loss.

Scenario 6: Limited Budget/Maintenance Cost Sensitivity – Prioritize Single ESCs

Core Need: Control long-term maintenance expenses and avoid "total failure due to one fault"

For drones used for casual daily flight (non-professional scenarios), users with limited budgets and a desire to avoid high maintenance costs will find single ESCs more reliable: For example, if one ESC burns out due to "motor jamming," only 30-50 yuan is needed to replace it, while the other 3 ESCs remain usable. With a 4-in-1 ESC, the entire module must be replaced for the same issue, costing 150-200 yuan—approximately 5 times more.

This "low-cost trial" feature is particularly friendly to students or entry-level users: Even if one ESC is accidentally burned during initial assembly, there is no need to repurchase the entire power system.